-

Phone

86-20-34****

-

Address

No. 1, North 3rd Industrial Park, Lanshan Village, Shatou Street, Panyu District, Guangzhou, Guangdong, China

-

E-mail

LatestProducts

Fine Polisher for Wardrobe Paint Plane Surface Mirror Finishing

Polisher, Paint Polisher, Surface Polisher

Description

Basic Info

- Model NO.: YL-ATPM-035

- Voltage: 380V, 50Hz

- Spindle Length: 600mm

- Grind Area: 3000mmx600mm (L*W)

- Trademark: Yi-Liang

- Specification: 6mX1.65mX1.65m (L*W*H)

- HS Code: 8460902000

- Weight: 2000kg

- Power: 7.5kw-4X1

- Spindle Speed: 1400 R/Min

- Work Table: 3000mmx600mm (L*W, Can Be Customized.)

- Transport Package: Wooden Case

- Origin: China (Mainland) Guangdong

Product Description

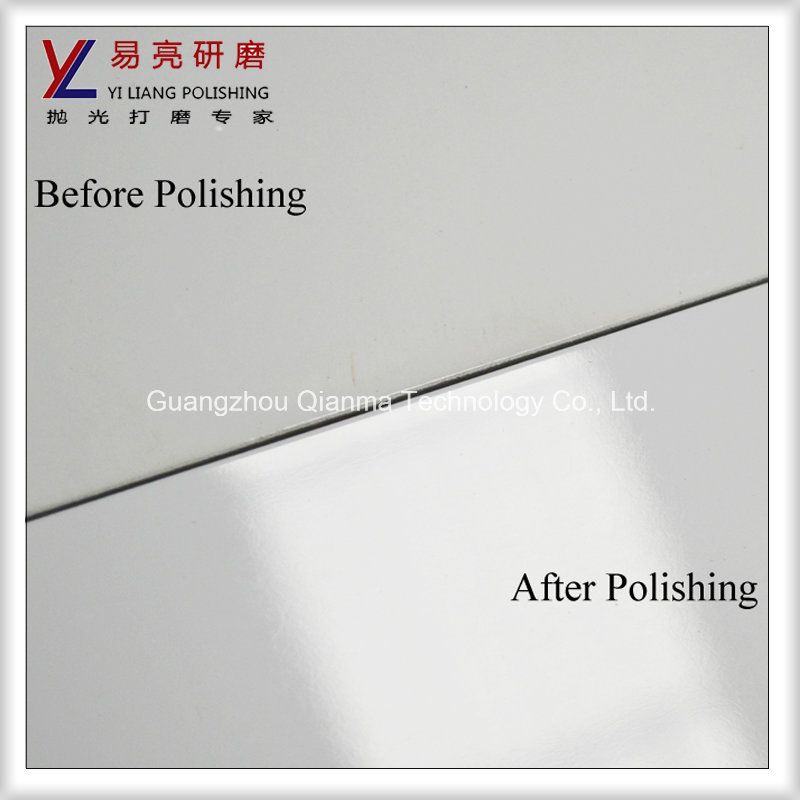

fine polisher for Wardrobe paint plane surface mirror finishing

YL-ATPM-035 polish machine is specially designed for paint board surface polishing.

Suitable for all kinds of paint panel flat surface polishing, such as cabinets, wardrobe, door, wooden tables and chairs plane surface.YL-ATPM-035 polish machine is specially designed for paint board surface polishing.

The present situation of paint surface polishing

In general, paint panel (large board) surface polish need 2 people operate at the same time, one of them responsible for paint surface polishing, and the other one is mainly hold the paint board on the behind, to maintain a relatively stable.

But people are active, with a certain of instability. If they move inadvertently during polishing, the board maybe not flat after polishing, which will directly lead to product quality decline.

And if the back one did not hold the panel tightly, or the machine rotated too fast, the board maybe flying forward or flip to the ground, which will hurt the operators.

Why choose us?

Our YL-ATPM-035 Paint Polish Machine is using vacuum suction function, when you start the machine, the vacuum suction will automatic sucking and fixing the panel.

This polishing machine only need 1 person to control the operate panel, and polishing time, frequency and polishing effect.

So the paint board polishing machine have the following advantages:

1. Ensure the stability of product quality.

2. Protect the safety of the operator.

3. Save labor costs.

4. Improve work efficiency.

5. Easy to operate.

6. Increase the replacement rate of professional polishing operator.

Machine Specification

| Volatge | 380V, 50HZ |

| Power | Main Motor: 7.5KW-4X1 |

| Horizontal swing: 550W-4X1 WPS70 | |

| Worktable in and out: 550W-4X1 WPS70 | |

| Conical motor: 0.4KW-4X1 WPS60 | |

| Spindle speed | 1400 r/min |

| Spindle length | 600mm |

| Worktable size | 3500mm*650mm (L*W) |

| Worktable travel | 3000mm |

| Grinding area | 3000mm*600mm (L*W) |

| Machine size | 6m*1.65m*1.65m (L*W*H) |

| Machine weight | 2000KG |

| Match abrasive tools | Fold cotton polishing wheels and liquid polishing wax. |